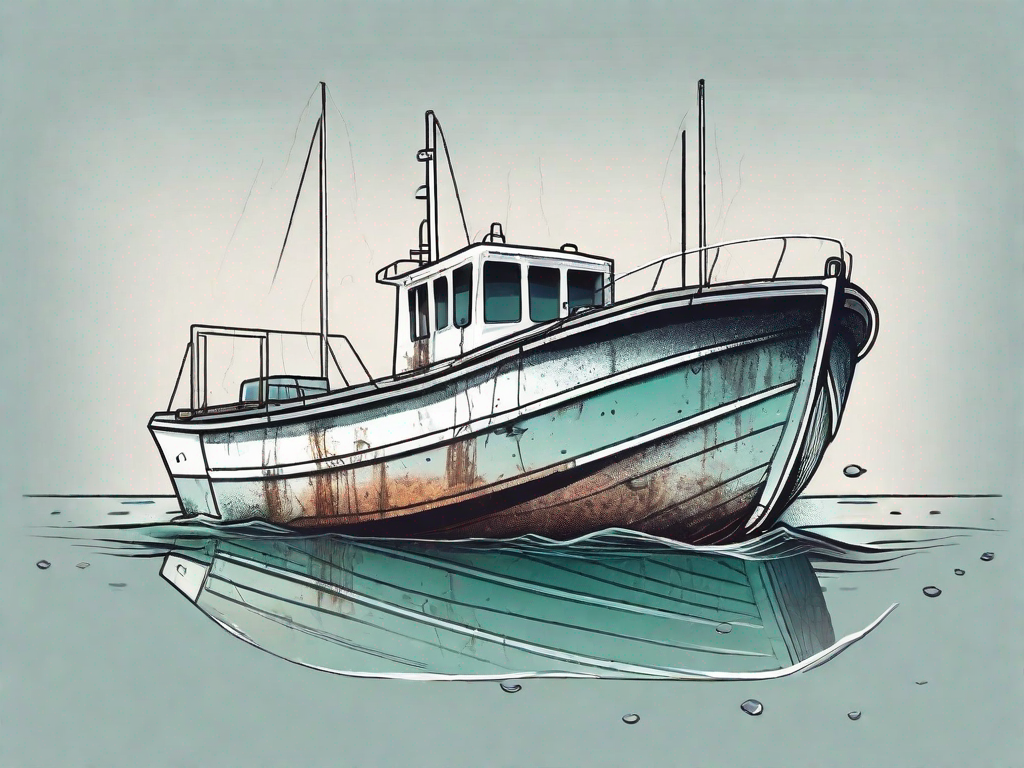

What Causes Corrosion for Watercraft?

Corrosion or fouling of hull surfaces has been an issue for as long as boats have been around. In today’s world of alloy boat hulls and metal surfaces, we continue to struggle with corrosion in the form of rust or pitting. While there are several factors that contribute to this oxidative process, some have questioned whether the use of aquatic herbicides for invasive and nuisance weed control contributes to accelerated corrosion.

While the idea seems logical, chemical treatments may not be the key factor people suspect.

Corrosive Forces and Sacrificial Anodes

Chemical treatments are commonplace in today’s world of recreational boat travel and water use. In order to freely use and enjoy our natural waterbodies, chemical herbicide treatments are used to maintain boatways, make swimming areas safer, and beautify shorelines.

However, this has led to the common misconception that these treatments are a leading cause of corrosion for metal boat hulls. While it is not an impossibility that they contribute, they are certainly not a leading cause of corrosion.

The construction of the modern boat hull, and propeller for that matter, involve the use different metals that can act as either an anode or cathode, with respective negative or positive charges.

In an article from the Aquatic Ecosystem Restoration Founsation (AERF) Brett Bultemeier From the University of Florida explains:

“The basic formula for a working battery that electrons from an electrolyte solution (acid for batteries) flow from the anode to the cathode. For those who have seen the corrosion old batteries can cause, this is similar to the galvanization that can occur in boats. The hull of a boat is commonly aluminum, which carries a negative charge, whereas propellers and other boat parts are made of materials that carry positive charges. Water carries enough electrolytes (even freshwater) to create conditions for galvanic corrosion.”

Essentially, the metal of your boat can act to complete the circuit of a battery, and cause galvanized corrosion.

Luckily, there are solutions to this problem, namely sacrificial anodes.

A sacrificial anode is an attachment made of Zinc, Magnesium, or Aluminum. These attachments preferentially corrode first, drawing the charge of electrolytes in the water to protect the hull and prop of the boat.

These work with or without current (charge) but they must remain submerged in order to work properly.

Chemical Treatment Impacts

In the same article, Bultemeier explains the short-lived nature of chemical treatments:

“Although it is true that in their undiluted form these chemicals can be corrosive, these chemicals are greatly diluted into a spray tank before being even further diluted into the lake water. Once in the treated water these chemicals are found at very low concentrations, as low as a few parts per billion and even at their highest only a few parts per million. “

Essentially, due to federal and state regulations, the products used in treatments are limited in the concentration they are applied at, to a dilution that would not have great impacts on boat surfaces.

If all lakes were without charge, as distilled or deionized water, then maybe these chemicals would be a significant factor for long-term corrosive action, but in lakes as they exist now, their contribution to enhanced corrosion is insignificant.